With the improvement of environmental awareness and the growth of hygiene needs, the market demand for flushable disposable toilet brush heads continues to expand. To meet this trend, we have developed equipment dedicated to the production of this product, aiming to provide efficient, stable and environmentally friendly solutions. The following is an analysis of the equipment from a technical perspective.

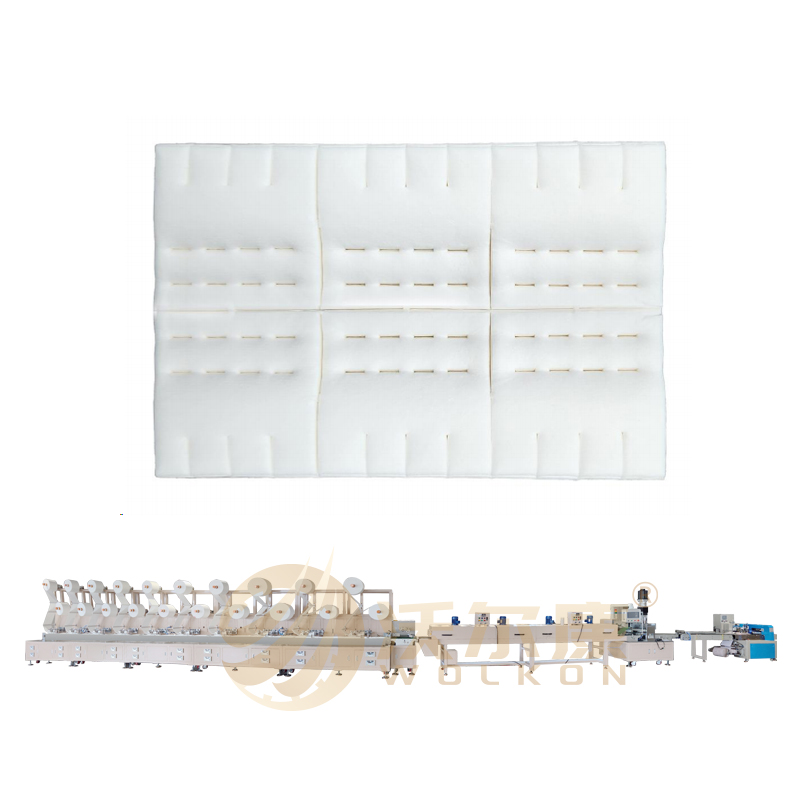

Fully automated production

The equipment adopts a modular design, integrating raw material transportation, molding, detergent injection, flushing performance control, packaging and other processes to achieve full-process automated production and significantly improve production efficiency.

High-precision control system

Equipped with high-precision sensors and PLC control systems, it can monitor and adjust key parameters such as brush head weight, detergent injection amount, and flushing speed in real time to ensure product consistency and stability.

Environmentally friendly and energy-saving design

The equipment uses low-power motors and environmentally friendly materials, with low noise and low energy consumption during operation, which meets green manufacturing standards. At the same time, the waste generated during the production process can be recycled to further reduce environmental impact.

Modular and customizable

The equipment adopts a modular design for easy maintenance and upgrading. Users can customize equipment specifications according to production needs and adapt to brush head products of different sizes, shapes and functions.

Intelligent operation interface

Equipped with a human-machine interface (HMI), the operation is simple and intuitive, and supports parameter setting, fault diagnosis and data recording, reducing the difficulty of operation and maintenance costs.

Raw material handling system

Adopt precision metering device to ensure accurate raw material ratio.

Equipped with temperature control system to optimize raw material fluidity and improve molding efficiency.

Molding and cleaning agent injection technology

High-precision mold design ensures consistent shape of brush head and smooth edge without burrs.

The quantitative injection system of detergent has an error control within ±1% to ensure the cleaning effect of the product.

Optimization of flushing performance

Through simulation testing and material optimization, it is ensured that the brush head can be quickly dispersed after use to avoid clogging the pipeline.

The equipment has a built-in flushing performance detection module to monitor the product compliance rate in real time.

Packaging and quality inspection system

Automated packaging unit supports multiple packaging forms (such as independent packaging, multi-piece packaging).

Equipped with a visual inspection system to automatically remove unqualified products to ensure factory quality.

Application scenarios

Suitable for manufacturers of daily necessities and cleaning products, especially those focusing on environmentally friendly products.

It can meet the production needs of different scales, from small batch trial production to large-scale mass production.

Technical advantages

Efficient and stable: high degree of automation, reducing manual intervention and improving production efficiency.

Quality assurance: high-precision control and detection system to ensure product qualification rate.

Environmental compliance: Comply with environmental regulations and help companies achieve green production.

This equipment focuses on the production needs of flushable disposable toilet brush heads. Through automated, intelligent and environmentally friendly designs, it provides users with efficient and stable production solutions. In the future, we will continue to optimize equipment performance, promote technological progress in the industry, and contribute to environmental protection.

For more technical details or customized solutions, please contact our technical support team.